We recently completed lime plastering work on two very different churches – St. Michael and St. John’s in Clitheroe and St. Paul’s in Blackley, Manchester.

Both had suffered from water ingress and failing plaster. Despite their age difference, the problems – and the right solutions – turned out to be very similar.

St. Michael and St. John’s, Clitheroe

The church’s history goes back to 1797, when Jesuit fathers from Stonyhurst began celebrating Mass for a small local congregation. The current Gothic Revival building, designed by J.A. Hansom and completed between 1847–1850, is built from limestone and sandstone.

We were subcontracted by Lloyd and Smith, a specialist restoration company, to carry out traditional lime plastering works. The architect’s specification required a fully traditional system using:

Cardewmires hot-mixed lime mortar for the scratch and levelling coats

A fine sand and lime putty mix for the finish coat

We sourced materials from our friends at Eden Hot Lime Mortars, who specialise in authentic hot mixes. These mortars are ideal for historic masonry – they allow the building to release moisture naturally and remain flexible over time.

St. Paul’s Church, Blackley

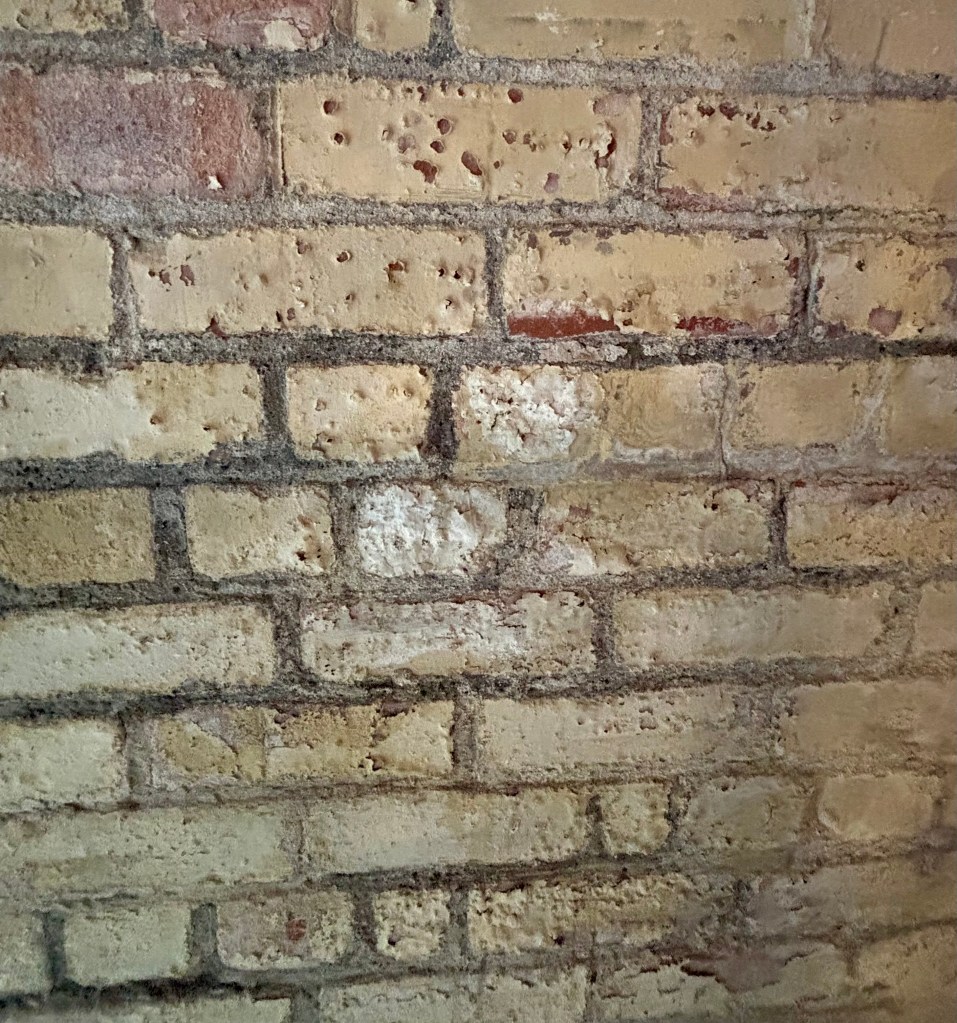

St. Paul’s Church was consecrated in 1931 at the hight of the depression and built from common brick. Originally planned to be larger, the nave was only part-finished due to financial issues at the time.

The interior plaster had become unsafe, with large areas delaminating from the wall. On inspection, we found it had been replastered over a painted surface using Carlite Bonding plaster – a popular gypsum premixed plaster containing vermiculite. Over time, it had lost adhesion and become unstable.

We stripped back all the loose material and decided the best approach was to replaster using a breathable, non-hydraulic lime system.

The process involved:

We chose Lime Coat by Best of Lime, known for its strength, adhesion, and flexibility – useful when working over difficult backgrounds.

Removing remaining paint and loose plaster

Applying Baumit DG27 primer to stabilise the surface without sealing it

Application of three-coats of non-hydraulic lime plaster

The result was a solid, vapour-open finish that allows moisture to escape – exactly what this type of wall needs to perform properly.

One Approach, Two Outcomes

Both churches were built a century apart using very different materials, but the same principle applied: traditional lime is the right choice for long-term performance.

In buildings like these, our approach at Natural Lime Finishes is always: remove the failing material, use a vapour-open system, and ensure the building can breathe. It’s what these two churches needed—and they now have a finish that will perform for many decades to come.

Written by Master Plasterer Mr Colin Morris